Joint Bar Inspection

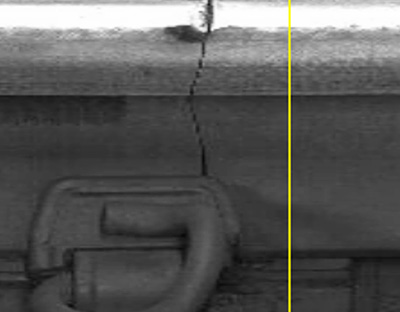

The JBIS performs automated crack detection on joint bars (fish plates) and rails. It also detects missing bolts according to business logic, measure rail gap, and deliver joint bar inventory reports. The system generates real-time exception reports, including continuous line scan images of suspect locations, and automatically inventories all joint bars and cracks in a permanent database.

Broken joints and rails are the leading factor of track caused derailments.

Broken joints and rails are the leading factor of track caused derailments.